Less maintenance and lower costs

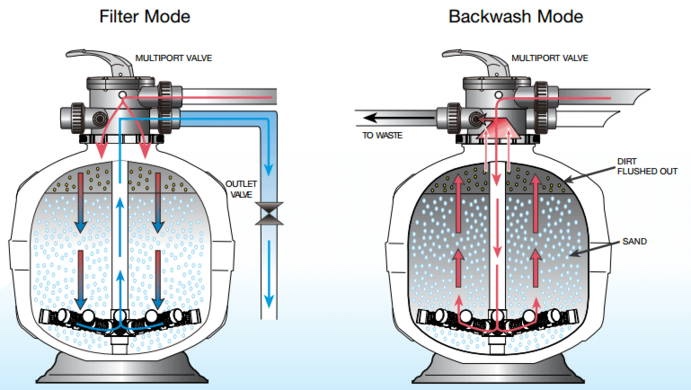

The solution is based on a sediment basin with a top-mounted grid. The volume of the basin is adapted to the capacity of the treatment plant. Incorporated into the sump, at the end where the outlet for the water is intended, is a dividing plate over which sedimented water flows and down into a smaller sump where a pump is installed. This pump then pumps the water further, with a pressure of 3-3.5 bar, to a filter with Selica sand.

A Silica sand filter is used instead of coal or other sand because Silica sand has an absorption of pollutants that is stable over a long period of time. Other materials have a reduced absorption of pollutants from day one and the filter material must be replaced in its entirety. When using Silica sand, it is calculated that approx. 15% new sand must be added each year.

From the Silica sand filter, the water goes in a hose to a 0.01 micron tubular filter. Filter with 0.01 micron fineness prevents viruses and bacteria. This helps to increase the safety of the water that is released into the sea or reused.

Both the Silica sand filter and the filter have automatic backwashing/washing. This water is returned in a separate pipe/hose to the sediment sump.

Backwashing/washing of the filters is carried out once a day, preferably when washing is not in progress. This is controlled via a PLS system which also controls level sensors in sediment basins etc.

Features/Advantages

Technical specifications

| Pump pressure: | 3-3,5 bar |

| Filter fineness: | 0,01 micron |

| Sand type: | Selica |

| Tube lifespan: | 3 years |